Did you know that using good inventory management software can cut costs by up to 30%? This fact shows the importance of choosing the right tools for your operations.

ERP systems help many departments in your company, while warehouse management software focuses on improving warehouse operations. Choosing between ERP vs WMS can greatly impact your efficiency, customer happiness, and business success.

This article will explain the key differences between ERP (Enterprise Resource Planning) and WMS (Warehouse Management Systems) and help you choose the best option for your business.

What is Enterprise Resource Planning Software (ERP)

ERP software is a powerful tool that automates and connects key business processes across different departments. It covers areas like accounting, inventory, human resources, and customer management. The goal is to make sure information flows smoothly between departments, increasing efficiency. Companies often use ERP systems to reduce the number of software connections. This simplifies processes and gives departments a unified experience.

Why is ERP Important?

ERP systems are important because they make operations smoother by linking different business tasks. This gives you a clear view of all your company's data. With up-to-date data, you can make smart choices that improve how things run and cut costs.

ERP systems help different departments work together better. They break down walls that can slow things down. With everyone having the same information, teams can quickly solve problems and grab new opportunities, which is essential for getting the most out of ERP.

These systems also help follow the rules, which is important in some industries. They offer tools to track and keep records of important business steps, making it easy to meet the rules without trouble.

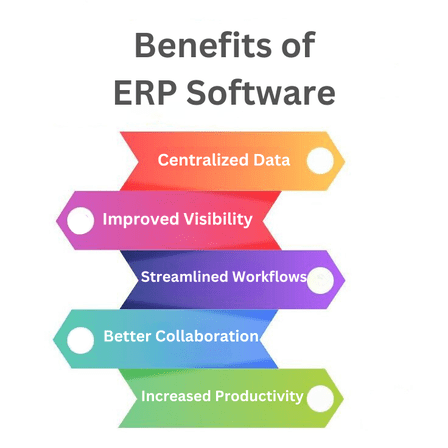

Benefits of ERP Software for Businesses

ERP software integrates different functions into one system, making your business more efficient and effective. Understanding the benefits of ERP can help you see how it can change your business.

Standardized and Centralized Data

One big plus of ERP is having one place for all your data. This stops different departments from having their own data, making things more accurate. With all data in one spot, you can make better decisions.

Improved Visibility

Real-time data means you can immediately see what's happening in your business. This lets you make changes quickly, which is key to getting the most from ERP. You can spot problems and chances to grow more easily.

Streamlined Workflows

ERP automates business processes, reducing manual work, mistakes, and delays. It also improves the quality of your offerings.

Better Collaboration

ERP lets different departments share info easily, which helps them work together better. This makes teams work more smoothly and leads to better projects. ERP's tools help spark new ideas and make things more efficient.

Increased Productivity

ERP also makes your team more productive. Automation means they can focus on important tasks instead of the same old things. This leads to a more creative team and helps your business grow and stay ahead.

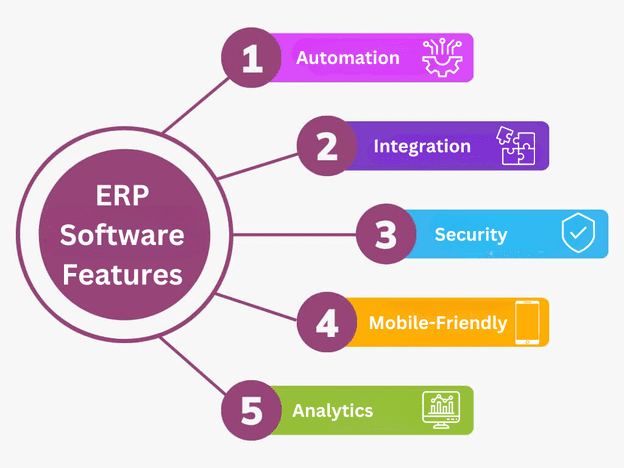

Top Features in ERP Software

Knowing the key ERP features helps pick the best software for your business. Here are some top ERP functionalities that improve business processes.

Automation and AI

ERP systems automate daily tasks, reducing manual mistakes. AI performs predictive analytics and gives smart process tips, improving decisions.

Seamless Integration and Scalability

ERP systems work well with many business apps. They grow with your business, offering scalable solutions. This means your software keeps up with your company's needs.

Better Security and Data Protection

ERP software has strong security to protect your data from hackers. It follows industry rules, making your data safe and trustworthy.

Mobile-Friendly and User-Centric Design

Modern ERP software works great on mobile devices. It's designed for users, making work easier and more productive, even from anywhere.

Real-Time Analytics and Reporting

ERP systems offer real-time analytics for better forecasting and smarter decisions. You get instant reports, giving you the insights you need fast.

What is a Warehouse Management System (WMS)

A Warehouse Management System (WMS) is key software that helps manage warehouse operations. It helps businesses keep track of inventory movement. This system ensures that products are received, stored, picked, packed, and shipped correctly, making processes smoother.

Why is WMS Important?

A Warehouse Management System is important because it helps increase efficiency by tracking inventory and optimizing warehouse space with real-time data. For businesses needing tight control over inventory and warehouse tasks, a WMS is a must-have. It leads to happier customers and lower costs.

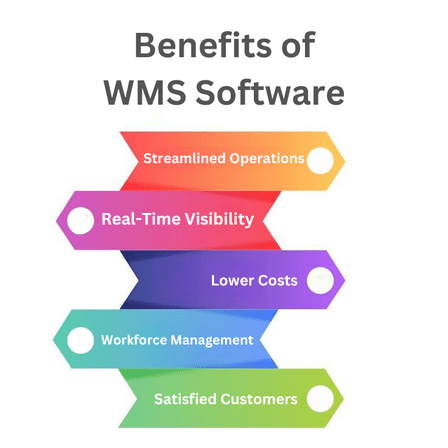

Benefits of WMS for Businesses

Using a Warehouse Management System (WMS) can greatly improve your operations. It makes things more efficient and productive. With a good WMS, you'll see many benefits that help your business succeed. Here are some of the most important advantages of using a WMS:

Automated and Streamlined Operations

A WMS automates important warehouse tasks, reducing mistakes. This speeds up key processes like picking and shipping and lets your team focus on tasks that add more value.

Real-Time Visibility

One big plus of a WMS is seeing your inventory levels and where they are in real-time. This information helps you manage stock better and avoid having too much or too little stock.

Optimized Space Utilization and Lower Operating Costs

A WMS helps you use your warehouse space more efficiently. It also ensures that storage is set up correctly, which saves money. Knowing these benefits can help you use your resources more effectively.

Effective Workforce Management

A WMS tracks how well workers are doing. It helps you use your team better based on what's needed. This makes your operations run smoother and keeps productivity high.

Improved Customer Service

With a WMS, you can track inventory and process orders faster. This means happier customers who come back, which is good for your business.

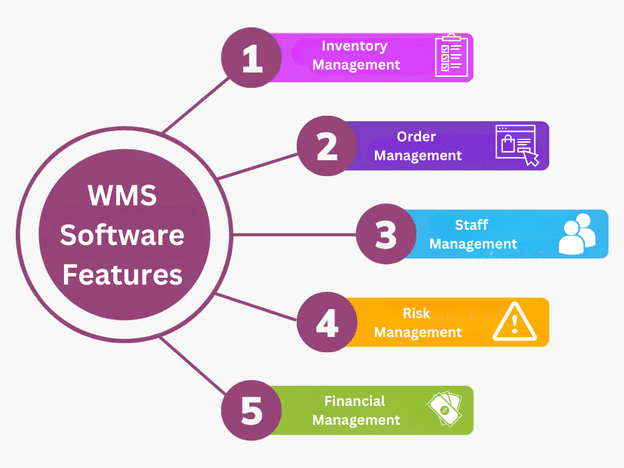

Top Features in WMS System

Understanding a Warehouse Management System (WMS) can increase your operations' efficiency. Each feature is key to smoother processes and improved performance. Here are the most important ones to look for:

Inventory Management

Effective inventory management is a top WMS feature. It tracks stock levels in real-time, which helps manage inventory better and reduces losses. With accurate data on what's in stock, you can decide when to restock and rotate items, making inventory management smarter.

Order Management

Order management keeps customers happy. A good WMS handles orders from start to finish, which means they are delivered on time and accurately. This reduces the chance of mistakes and keeps customers satisfied, which is key to meeting customer expectations.

Staff Management

WMS staff management tools give insights into how employees work. You can see who's doing well and assign tasks better, resulting in a more efficient team. Managing your team well makes operations run smoother and increases the quality of work done.

Risk Management and Forecasting

Risk management and forecasting tools in WMS help predict inventory needs. If you know what to expect, you can avoid issues like stockouts or overstocking. This keeps inventory levels just right and cuts down on waste.

Financial Management and Reporting

Some WMS systems track costs for warehouse operations and offer detailed reports on their performance. This helps with cost tracking and budget planning.

Key Differences Between ERP and WMS

The differences between ERP and WMS are mainly about their focus. ERP systems handle core business tasks across different departments. They provide a single platform for data and operations. WMS, on the other hand, focuses on managing warehouses and inventory and offers tools to improve these areas.

An ERP vs WMS comparison shows that both can manage inventory. However, WMS handles warehouse tasks better, such as tracking stock and fulfilling orders. This makes WMS crucial for businesses with big warehousing needs. ERP, however, is for managing all business areas, including finance, HR, and customer relations.

Think about what your business really needs. If you need detailed warehouse management, choose WMS. ERP might be better if you want to manage your whole business and connect different departments.

| Feature | ERP | WMS |

| Primary Focus | Comprehensive business management | Warehouse and inventory optimization |

| Functionality | Integrated across departments | Specialized warehouse control and automation |

| Inventory Management | Basic capabilities | Advanced tracking and control |

| Suitability | All businesses | Businesses with extensive warehousing needs |

| Data Centralization | Yes, across all functions | No, primarily for warehouse data |

The Pros and Cons of ERP vs WMS

Looking at the pros and cons of ERP systems, their unified approach is clear. They help different departments work together better, making the business run smoother. But they can be pricey, especially when adding features like analytics or extra modules.

Warehouse management systems (WMS) are all about improving warehousing. The pros and cons of WMS show that they're great at tracking inventory and managing stock. They help us space well and ensure that orders are accurate. However, WMS might not work well with other parts of the business unless it's fully integrated with an ERP, leading to separate parts within the company.

| Criteria | ERP | WMS |

| Integration | Cross-departmental, centralized data | Specialized for warehousing, may need ERP to connect |

| Cost | Higher initial investment with ongoing costs for additional features | Lower initial investment, focuses on warehousing needs |

| Functionality | Comprehensive business management | Focused warehouse operations improvement |

| Scalability | Flexible with growth but can become complex | Designed to scale within warehouse operations |

| Data Visibility | Real-time insights across the organization | Detailed tracking and management of inventory |

ERP vs WMS: Which is Better for Your Business

Choosing between ERP and WMS requires careful thought about your business's needs. Think about what your company requires to make the right choice. Here are important points to consider when picking between ERP and WMS for your business.

Understand Your Industry

Your industry is key in deciding between ERP and WMS. If your business deals with warehousing, a WMS is better for managing inventory and warehouse tasks. But if you need to manage many different functions, an ERP system might be a better fit.

The Importance of Business Size

How big your business is also matters. Small businesses might just need a WMS for better efficiency. However, big companies often need ERP systems to handle complex workflows between departments, improving teamwork and productivity.

Organizational Requirements

Every business has its own set of needs. Look at your current processes to see if ERP or WMS is better for you. A detailed review of your needs helps you find the right features for your goals.

Identify Strengths and Weaknesses

It's important to know your business's strengths and weaknesses. If you're good at managing data and resources, an ERP system is likely the best choice. But, if your warehouse operations are strong, a WMS could be a better fit.

Long-Term Objectives

Think about your long-term goals when making a decision. Consider how each system fits with your future plans. An ERP system might help you grow into new markets or product lines. A WMS could make your warehouse operations more efficient.

Manage Your Operations with Kohezion

Kohezion is a flexible platform that can function as both an ERP and a WMS, providing everything your business needs in one place. With Kohezion, you can combine different parts of your business, such as finance, HR, and supply chain management, into a single system.

This allows you to streamline warehouse tasks like inventory management, order processing, and real-time tracking while handling broader business goals like forecasting and financial planning. Whether you need to improve warehouse efficiency or manage your entire business, Kohezion offers the tools and flexibility to meet your needs. Our platform helps you make informed decisions and improve operations across your organization.

| Feature | Benefit |

| Inventory Tracking | Real-time visibility of stock levels, reducing overages and shortages |

| Order Management | Streamlined order fulfillment processes improve customer satisfaction |

| Analytics Tools | Informed decision-making backed by actionable data insights |

| ERP Integration | Seamless process flow, minimizing operational disruptions and errors |

| Team Collaboration | Improved communication leads to more efficient task management |

Start building with a free account

Conclusion

Understanding the differences between ERP and WMS systems is crucial for businesses looking to optimize their operations. An ERP system provides a comprehensive solution by integrating different business functions, such as finance, human resources, and supply chain management, into a single platform.

On the other hand, a WMS offers specialized capabilities for managing warehouse operations, including inventory control, order fulfillment, and real-time tracking. Choosing between ERP and WMS depends on your business’s specific needs, industry requirements, and growth objectives. For some businesses, an integrated approach using both systems may be the best option to achieve operational efficiency and scalability.

If you need assistance determining which system is right for you or have any questions, feel free to contact us at Kohezion. Our team is here to help you find the best solution for your business.

Frequently Asked Questions

ERP (Enterprise Resource Planning) software in a warehouse is a comprehensive system designed to manage and integrate different business functions across the organization, including inventory, procurement, and order processing.

ERP software helps streamline operations in a warehouse context by providing real-time visibility into inventory levels, order status, and supply chain activities. It supports demand forecasting, procurement planning, and financial management, improving efficiency and decision-making.

A Warehouse Management System (WMS) specializes in automating specific tasks related to warehouse operations that ERP systems may not handle as effectively. Tasks such as real-time inventory tracking, order picking, and packing are managed with high precision and efficiency by a WMS.

WMS solutions can also optimize warehouse layout and streamline workflows to improve space utilization and reduce handling time, which are areas typically beyond the scope of general ERP systems.

Yes, it is possible to integrate a WMS with an ERP system, and doing so can provide significant benefits. Integration allows for seamless data flow between the warehouse and other business functions such as finance, sales, and procurement.

This enables accurate inventory management, improved order fulfillment, and improved reporting capabilities, ultimately contributing to more efficient operations and better organizational decision-making.