Many companies are turning to ERP (Enterprise Resource Planning) systems to tackle challenges like stringent regulations, pricing pressures, and increasing operational costs. This article will provide an in-depth overview of the best Pharma ERP software to consider in 2024.

We'll buid your first application for you. At no extra cost.

Let us build your first business application for free. Go from an idea to an application in under 2 weeks.

What is Pharma ERP Software?

Pharma ERP software is a specialized type of Enterprise Resource Planning system tailored specifically for the pharmaceutical industry. It acts as the central nervous system of a pharmaceutical company, integrating various functions such as production, quality control, compliance, inventory management, and sales into a cohesive unit.

This software is built to handle the unique challenges of the sector, including stringent regulatory requirements, complex manufacturing processes, and the need for accurate, real-time data.

Why is Pharma ERP Software Important?

Choosing the right Pharma ERP software has significant implications for a pharmaceutical company. It sets the foundation for the entire operation mechanism of the organization. A well-tailored ERP system can help a pharmaceutical company adhere to stringent compliance requirements, manage complex supply chains involving restricted substances, and ensure fast inventory turns due to perishable goods.

The pharma industry's heavily regulated nature demands extensive tracking, accountability, and reporting, which could be highly time-consuming and prone to errors without the help of an efficient ERP system. Hence, it's critical to select an ERP that's specially designed for the pharmaceutical industry, keeping in view all these requirements. Being strategic about the choice can ultimately lead to streamlining business processes, increasing operational efficiency, meeting regulatory compliance, and enhancing overall productivity.

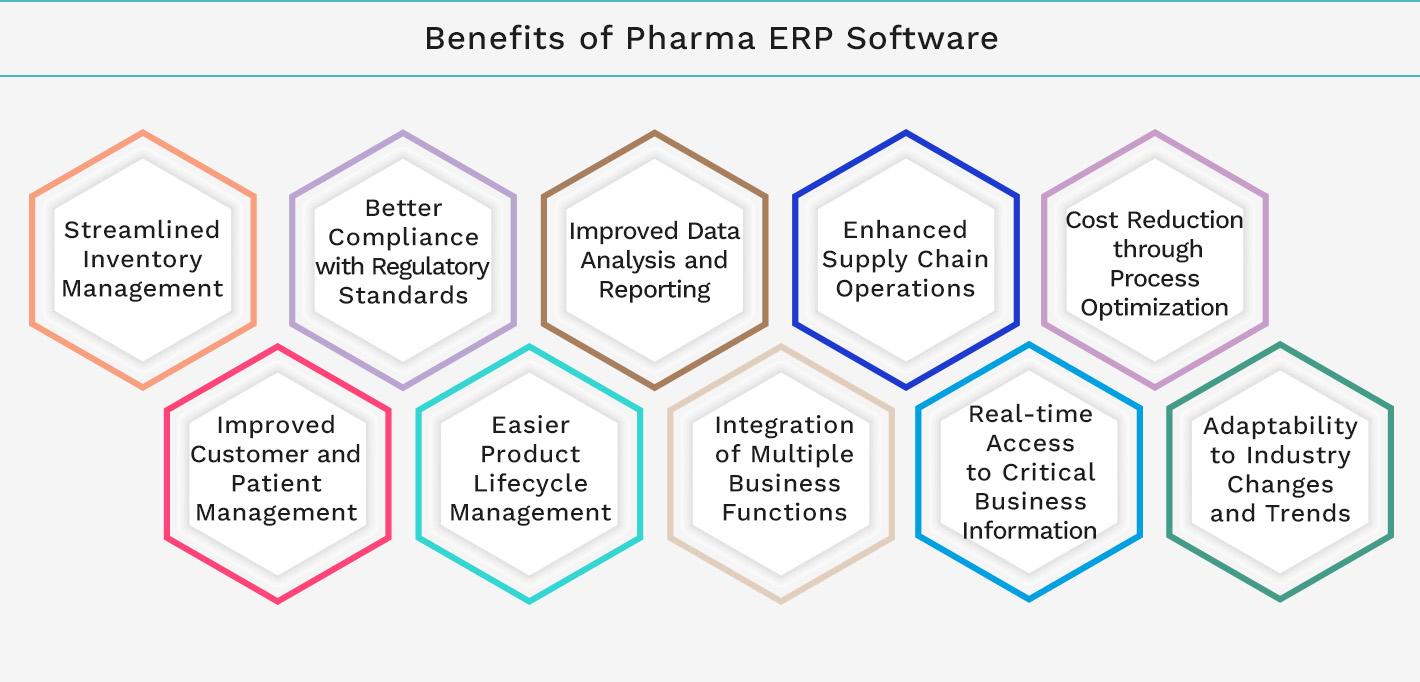

Benefits of Pharma ERP Software

A Pharma ERP system not only drives day-to-day operations but also helps in quality monitoring, inventory management, cost analysis, and regulatory compliance. It boosts the overall business performance and streamlines complex processes in an increasingly demanding industry.

Streamlined Inventory Management

Smart inventory management becomes the norm, enabling you to dodge stock-outs, reduce waste, and ensure the timely delivery of pharmaceutical essentials. With features like real-time tracking of expiration dates and batch tracking, you'll optimize stock levels effortlessly. Replace cumbersome manual processes with this automated, error-reducing and efficiency-boosting approach.

Better Compliance with Regulatory Standards

Pharma ERP software simplifies compliance within the complex landscape of healthcare regulations. This solution ensures adherence to critical standards such as FDA’s 21 CFR Part 11, EMA guidelines, and GMP protocols. It offers automated audit trails, rigorous quality control, and robust reporting tools. Beyond avoiding penalties, Pharma ERP plays a crucial role in maintaining the safety and efficacy of life-saving drugs that our community relies upon.

Improved Data Analysis and Reporting

Designed to cut through the noise, this software provides powerful data analysis and reporting capabilities. Managers and department heads can now conjure detailed, insightful reports within minutes, minus the hassle of IT bottlenecks. Empowered by real-time data and analytical dashboards, you can make informed decisions faster and forecast with precision, pivoting strategically as market dynamics shift.

Enhanced Supply Chain Operations

Pharma ERP software integrates various processes, such as procurement, inventory management, and distribution, into a unified system, and improves the visibility and traceability across the supply chain. This integration allows for real-time monitoring and data analysis, enabling better demand forecasting, reducing stockouts and overstock situations, and ensuring compliance with regulatory standards.

Cost Reduction through Process Optimization

Pharma ERP software automates the routine tasks, reduces manual errors, and streamlines operations across various departments. It enhances resource allocation, minimizes waste, and improves inventory management, ensuring that materials are used efficiently and costs associated with excess inventory or stockouts are avoided. It also facilitates better supplier management and negotiation, leading to more favorable terms and reduced procurement costs.

Improved Customer and Patient Management

Pharma ERP software builds bridges to better healthcare, where managing customer and patient relationships is as therapeutic as the medications provided. The CRM integration stands out as it diligently catalogs interactions and preferences, ensuring customer service representatives deliver personalized and empathetic support. For patients, the ERP's clear tracking of medical history and medication interactions promises enhanced safety and care. In this environment, nurturing strong, trusting relationships with customers and patients isn't just good practice—it's a seamless aspect of your day-to-day ecosystem.

Easier Product Lifecycle Management

Pharma ERP software brings a sense of calm to the often tempestuous seas of product lifecycle management (PLM). From concept to consumer, track every stage with unprecedented ease and precision. Manage formulations, collaborate seamlessly across departments, swiftly respond to market feedback, and ensure no detail is lost in the shuffle. When PLM is made easier, innovation flourishes, and products that meet and exceed consumer expectations become the norm, not the exception.

Integration of Multiple Business Functions

Pharma ERP software consolidates various departmental processes, such as manufacturing, finance, quality control, and sales, into a single cohesive system. This integration ensures seamless data flow and communication across the organization, enhancing coordination and reducing silos. With a unified platform for managing all aspects of the business, the software enables real-time access to critical information, facilitates cross-functional collaboration, and supports strategic decision-making. This holistic approach not only improves operational efficiency but also ensures that all departments work towards common goals, optimizing overall business performance.

Real-time Access to Critical Business Information

Pharma ERP software centralizes data from various departments into a single, integrated platform, allowing users to retrieve and analyze up-to-date information instantly. This immediate availability of data supports timely decision-making, enhances responsiveness to market changes, and improves operational efficiency. The real-time reporting and analytics tools enable stakeholders to monitor key performance indicators, track inventory levels, and oversee production processes, ensuring that the organization can swiftly address any issues and maintain regulatory compliance.

Adaptability to Industry Changes and Trends

Pharma ERP software offers customizable modules and flexible workflows that can be easily adjusted to accommodate new regulations, market demands, and technological advancements. Its scalable architecture allows businesses to integrate new functionalities and processes as needed, ensuring they stay current with industry standards and best practices.

10 Top Rated Pharma ERP Software

1. Kohezion

Kohezion stands out in the Pharma ERP arena, earning accolades for its user-friendly interface and customized application builder. Users appreciate the ability to craft tailor-made solutions that address their unique pharmaceutical requirements without writing a line of code. It's not just about flexibility; it's about empowerment, with Kohezion's platform facilitating better data management and operational efficiency. This makes it an excellent choice for businesses striving for innovation and agility in their ERP solutions.

Top 5 Features:

- Custom application builder

- No-code software environment

- Robust data management capabilities

- Scalable platform for businesses of all sizes

- Intuitive user interface for ease of use

Benefits:

- Reduces dependency on IT staff for app development

- Tailors features to suit precise industry needs

- Streamlines operations through efficient data handling

- Grows with your business without requiring a complete overhaul

- Minimizes training time due to an easy-to-navigate design

Cons:

- May require time to fully explore and utilize customization options

- Could be overwhelming for users unfamiliar with designing applications

Best For:

- Pharmaceutical companies seeking a highly customizable and scalable ERP solution that can evolve with their business needs without extensive technical know-how.

2. Oracle NetSuite

Oracle NetSuite is one of the top-rated ERP solutions, well-admired for its cloud-based technology and comprehensive financial management capabilities. It offers a singular platform to integrate and streamline the entirety of operations, including procurement, project management, and financials.

NetSuite specifically caters to the distinct needs of the pharmaceutical industry. It provides real-time visibility into inventory levels, expiry dates, and lot numbers— an essential feature in the pharmaceutical industry for avoiding wastage and ensuring compliance with regulations.

Its compliance management suite enables rigorous tracking and documentation for all facets of production and distribution, ensuring that every process meets regulatory standards.

The financial management component of Oracle NetSuite, encompassing accounts payable, accounts receivable, general ledger, and financial reporting, allows pharmaceutical companies to track and manage finances across multiple locations. With personalized dashboards and analytics, it enables decision-making in real-time, resulting in stronger operation outcomes.

Top 5 Features:

- Cloud-based technology for accessibility and security

- Real-time analytics and personalized dashboards

- Flexible financial management modules

- Streamlined project and supply chain management

- Regular automatic updates to keep up with industry standards

Benefits:

- Enables remote access to critical data and operations

- Provides insights to drive smarter, faster business decisions

- Customization options to meet unique financial scenarios

- Enhances efficiency in project execution and resource planning

- Ensures the ERP system remains current without manual intervention

Cons:

- More suitable for larger enterprises, possibly out of reach for smaller businesses

- The extensive array of features may require a steeper learning curve

Best For:

- Larger pharmaceutical companies looking for a scalable, cloud-based ERP solution with a strong emphasis on analytics and continuous improvement.

3. SYSPRO

SYSPRO, with its deep integration capabilities and industry-specific features, makes it a prominent player for Pharma ERP. It caters particularly well to small and mid-sized pharma distributors, offering a robust platform that supports everything from formulation management to supply chain and finance. SYSPRO's ability to accommodate different business models and its flexible deployment options—be it cloud, on-premise, or hybrid—add to its attractiveness, particularly for businesses in the growth phase seeking a system that can adapt to evolving needs.

Top 5 Features:

- Cloud-based technology for accessibility and security

- Real-time analytics and personalized dashboards

- Flexible financial management modules

- Streamlined project and supply chain management

- Regular automatic updates to keep up with industry standards

Benefits:

- Enables remote access to critical data and operations

- Provides insights to drive smarter, faster business decisions

- Customization options to meet unique financial scenarios

- Enhances efficiency in project execution and resource planning

- Ensures the ERP system remains current without manual intervention

Cons:

- More suitable for larger enterprises, possibly out of reach for smaller businesses

- The extensive array of features may require a steeper learning curve

Best For:

- Larger pharmaceutical companies looking for a scalable, cloud-based ERP solution with a strong emphasis on analytics and continuous improvement.

4. SAP S/4 HANA

SAP S/4 HANA stars on the Pharma ERP stage, bringing together a powerful blend of advanced in-memory technology, AI, and analytics to serve large-scale enterprises adeptly. It’s a premium solution favored by establishments desiring a sophisticated platform capable of handling complex, global operations while providing extraordinary data processing speeds. With SAP S/4 HANA, firms gain the agility to make swift adjustments in response to market fluctuations and can execute effective decision-making backed by real-time insights.

Top 5 Features:

- In-memory database for fast processing and analytics

- AI and machine learning capabilities for predictive insights

- Extensive integration with other SAP modules and external systems

- Focus on financial planning and governance, tailor-made for large entities

- Support for diversified business models in the pharmaceutical industry

Benefits:

- Accelerates performance with quicker data retrieval and analysis

- Empowers businesses with predictive capabilities for proactive strategies

- Facilitates seamless connectivity for enterprise-wide process optimization

- Delivers superior financial control and traceability

- Adapts to various global pharmaceutical business models within a unified framework

Cons:

- May present a steep learning curve due to its breadth of advanced functionalities

- Cost and complexity might be prohibitive for smaller operations

Best For:

- Larger pharma enterprises with diverse, global needs that require an ERP system with superior processing power and an extensive range of features.

5. WinMan

WinMan ERP software comes as a highly capable solution, making its mark for businesses that value visibility and control over their data and processes. It’s a reliable choice for those seeking a .NET-based, end-to-end system designed with unlimited user capacity, making it ideal for growing pharmaceutical companies. WinMan supports crucial facets of the industry from supply chain management to compliance, emphasizing its use for those who prioritize data-driven decision-making and process integration.

Top 5 Features:

- Unlimited user capacity on a .NET framework

- Real-time data insights across all business operations

- Streamlined process management from procurement to sales

- Robust compliance and quality control features

- Comprehensive financial management and reporting tools

Benefits:

- Allows a flexible, scalable approach to user management, supporting business growth

- Provides access to critical data for immediate visibility and informed decision-making

- Integrates various processes for smoother, more efficient business workflow

- Ensures adherence to industry compliance standards and quality regulations

- Bolsters financial oversight, leading to better cost management and profitability

Cons:

- Might require customization to align perfectly with specific pharma processes

- The intensive data and process integration can demand a detailed initial setup

Best For:

- Pharmaceutical companies, especially those in a growth phase, looking for an ERP system that can accommodate an increasing number of users without compromising performance or accessibility.

6. Sage Intacct

Sage Intacct earns its stripes in the Pharma ERP domain with its cloud-based financial management prowess. It's particularly fitting for upper-mid to large pharma companies that require a robust ERP solution with strong emphasis on accounting and financial operations. With Sage Intacct, you benefit from exceptional supply chain management and a deep pool of functionality, right out of the box. Their ecosystem of consultants is commendable, especially for ensuring pharma validation, making it a comprehensive package for the sector.

Top 5 Features:

- In-depth financial management and reporting

- Real-time operational and financial visibility

- A set of comprehensive supply chain management tools

- Advanced security and compliance features

- Granular accessibility controls for fine-tuning user permissions

Benefits:

- Facilitates detailed financial oversight and smarter financial decisions

- Empowers users with instant insights into financial and operational metrics

- Enhances supply chain fluency, leading to streamlined operations

- Upholds rigorous compliance with industry regulations and safeguards data integrity

- Maintains strict access protocols, minimizing unauthorized data exposure

Cons:

- Not ideally suited to the smaller scale pharma companies due to its robust design

- May necessitate partnering with consultants for initial customization or validation

Best For:

- Larger pharmaceutical companies seeking an ERP solution with exceptional financial management capabilities and a system that ensures compliance with stringent industry regulations.

7. Blue Link ERP

Blue Link ERP carves its niche for mid-sized pharmaceutical distribution companies looking for ERP solutions that can manage the unique demands of the pharma industry without the complexity and heft meant for larger enterprises. It's a boutique option that's adept at navigating the regulatory landscape while streamarily managing day-to-day activities, from inventory to sales. Not quite the juggernaut for heavy-duty manufacturing, Blue Link still delivers in spades where it counts for its target market, providing streamlined functionality and technical smarts.

Top 5 Features:

- Specialized tracking for suspicious drugs

- ARCOS and CSOS reporting capabilities

- Integration with TI/TS/TH transmission via EDI

- Microsoft SQL Server database for robust data storage

- Expertise in DSCSA compliance and regulatory updates

Benefits:

- Offers targeted functionality for specific last-mile pharma distribution needs

- Ensures compliance with intricate drug monitoring requirements

- Facilitates secure and efficient data transactions within the supply chain

- Leverages a stable and high-performing technical infrastructure

- Keeps pace with regulatory changes, providing timely system updates

Cons:

- May not suit very large pharma manufacturers with more extensive needs

- Could present a limited ecosystem for finding specialized talent

Best For:

- Mid-sized pharma distribution firms looking for a tailored ERP solution that prioritizes regulatory compliance and efficiency without the overhead designed for larger companies.

8. AX for Pharma

AX for Pharma stands tall as a titan in the Pharma ERP landscape. It's not just a software solution; it's a transformational force designed specifically for the pharmaceutical industry, embracing the most meticulous manufacturing and distribution needs. Engineered on the robust Microsoft Dynamics 365 platform, AX for Pharma delivers a full-throttle experience that controls every process with precision, eases compliance burdens, and cranks out real-time analytical insights to keep you ahead in the market. Whether you're overseeing the production line or the journey of your products from lab to patient, this solution ensures efficiency and adherence to strict regulatory standards.

Top 5 Features:

- Deep integration with Microsoft Dynamics 365

- Custom-tailored modules for pharma-specific operations

- Automatic data capture and inventory reconciliation

- Streamlined clinical trials management

- Advanced quality management integrated into core processes

Benefits:

- Drives operational excellence andutilizes established industry best practices

- Adhers to GMP and other regulations and reduces the risk of compliance issues

- Offers real-time data for accurate demand forecasting and decision-making

- Simplifies complex clinical trials and enhances product development cycles

- Boosts warehouse and supply chain performance, reducing order fulfillment times

Cons:

- May require investment in training for users to fully leverage all features

- Could be perceived as offering more than needed for very small enterprises

Best For:

- Pharmaceutical companies seeking an all-encompassing, integrated ERP system that offers specialized functionality and compliance ease, all built on a trusted Microsoft platform.

9. Aptean Process Pro

Aptean ProcessPro takes its rightful place in the Pharma ERP lineup, specifically shining for small to medium-sized process manufacturers needing a heavyweight in manufacturing capabilities. Its forte lies in formulation management and batch manufacturing, critical for the pharmaceutical industry. Aptean ProcessPro not only supports these core functionalities but also delivers tools that enhance speed, reduce costs, and minimize labor, making it a sturdy pillar for pharma companies focused on operational excellence.

Top 5 Features:

- Comprehensive formulation and recipe management

- Strong batch production and tracking tools

- Robust material requirements planning (MRP)

- Detailed quality control and compliance modules

- Fully integrated financial and customer management

Benefits:

- Ensures precision and consistency in product formulation

- Maintains stringent control over batch production for safety and quality

- Optimizes inventory levels and raw material usage

- Supports adherence to strict industry standards and regulations

- Manages financial transactions and customer relations seamlessly

Cons:

- User interface may seem dated compared to more modern ERP solutions

- Smaller ecosystem could limit support options outside the Aptean network

Best For:

- Small to medium-sized pharmaceutical manufacturers that require robust manufacturing capabilities with an emphasis on formulation and batch processes.

10. Microsoft Dynamics 365

Microsoft Dynamics 365 Business Central scoops a top spot among Pharma ERP solutions for its versatility and native integration with familiar Microsoft tools. This cloud-enabled powerhouse is ideal for small to mid-sized businesses wanting a comprehensive, scalable ERP that grows as they do. Dynamics 365 Business Central offers real-time cloud access and a user-friendly experience with the look and feel that so many already know. It's a multi-faceted platform that can handle finance, manufacturing, and sales, ensuring that your pharma business is always on the ball.

Top 5 Features:

- Seamless integration with Microsoft Office tools

- Cloud-based solution providing universal access

- Scalable to fit business growth and expansion

- A strong suite of financial management tools

- Advanced inventory and supply chain management capabilities

Benefits:

- Improves productivity with a familiar interface and software ecosystem

- Provides flexibility with anywhere access to critical business operations

- Eases the growing pains of businesses with its adaptable structure

- Delivers robust financial insight to optimize revenue and cost management

- Streamlines the supply network, from procurement to customer delivery

Cons:

- May require additional customization for complex, industry-specific needs

- Smaller organizations could find the cost per user slightly prohibitive

Best For:

- Small to mid-sized enterprises that need a fully integrated ERP system to coalesce their various business functions, especially those deeply ingrained in the Microsoft software environment.

Key Features to Look for in a Pharma ERP Software

Given the complex and heavily regulated nature of the pharmaceutical industry, it's vital to consider certain specific modules while choosing a Pharma ERP solution. The software must align with pharmaceutical processes and regulatory compliance to ensure efficient and hassle-free operations. Here are some key features to look for:

Batch and Recipe Management

Pharma ERP software's batch and recipe management feature ensures precise control over production processes by enabling the creation, modification, and tracking of detailed recipes and batch records. This feature allows for accurate formulation, consistent quality, and compliance with regulatory standards by managing ingredient quantities, production steps, and process parameters.

It also facilitates traceability by maintaining comprehensive records of each batch, from raw material sourcing to finished product, thereby enhancing quality control and enabling quick responses to any issues or recalls.

Regulatory Compliance

Pharma ERP software automates compliance-related processes, maintaining accurate and up-to-date records, and providing tools for auditing and reporting. It helps manage documentation, track changes, and ensure that all procedures meet regulatory requirements, such as Good Manufacturing Practices (GMP) and FDA guidelines.

The software also facilitates electronic signatures and secure data storage, enhancing traceability and accountability, which simplifies the process of passing regulatory inspections and audits, thereby reducing the risk of non-compliance and associated penalties.

Quality Management

With an embedded Quality Management System (QMS), such ERP software ensures that the highest standards are not only met but exceeded. This crucial module offers features like on-the-fly tracking of production quality, real-time feedback loops, and robust capabilities for handling Corrective and Preventive Actions (CAPA). With the integration of QMS with ERP, your operation is poised to deliver products that are safe, efficacious, and stand the rigorous scrutiny of regulatory bodies.

Traceability

With full visibility from raw material sourcing to final delivery, these systems make tracking a streamlined process, rather than a scramble in times of crisis. Whether it's honing in on a single ingredient's origin or mapping a product’s journey to a patient's hands, modern traceability functionalities are designed to instill confidence and accountability at every stage of the supply chain.

Inventory Management

The right ERP system keeps medications in check and operations smooth, offering lightning-quick information on stock levels, demand forecasts, and even shelf life. With automated ordering that kicks in just before you hit critical lows, you dodge stockouts and waste, ensuring that your company can fulfill orders on time, every time, without the drag of overstocking.

Financial Management

Pharma ERP software's financial management feature integrates accounting functions with other business processes. It automates financial reporting, budgeting, and forecasting, allowing for real-time visibility into revenue, expenses, and profitability across the organization. This feature enables efficient management of cash flow, invoicing, and financial transactions while ensuring compliance with accounting standards and regulations.

Supply Chain Management

Pharma ERP software integrates and optimizes procurement, inventory management, and distribution processes. It enables real-time tracking of inventory levels, facilitates demand forecasting, and supports efficient supplier management. The software streamlines order processing, reduces lead times, and minimizes stockouts, ensuring continuous supply while managing costs effectively..

Reporting and Analytics

Pharma ERP software's reporting and analytics feature offers robust tools to gather, analyze, and visualize data across various business functions. It provides comprehensive insights into key performance indicators, production metrics, financial trends, and regulatory compliance.

The software generates customizable reports and dashboards in real-time, and enables stakeholders to make data-driven decisions promptly, optimize processes, and identify opportunities for continuous improvement. This capability enhances transparency, efficiency, and strategic planning within pharmaceutical companies, supporting their overall growth and competitiveness in the industry.

Serialization

Pharma ERP software assigns and manages unique identifiers to individual units or batches of pharmaceutical products throughout the supply chain. It enables traceability from production through distribution and to the end consumer, enhancing visibility and security against counterfeit products.

The software captures and stores serialization data in a centralized database, which facilitates rapid retrieval and verification, aiding in quick response to recalls or regulatory inquiries. This capability not only safeguards patient safety but also strengthens supply chain integrity and regulatory compliance for pharmaceutical companies.

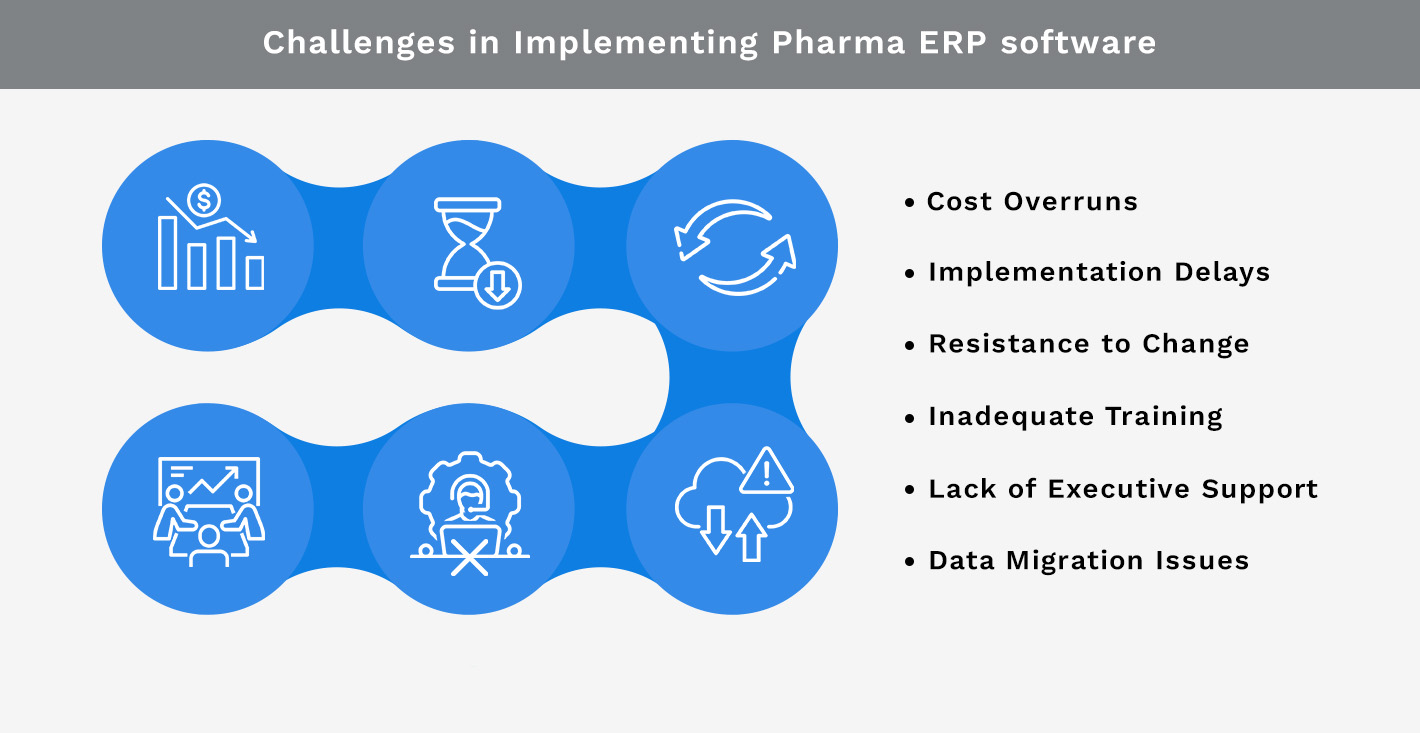

Challenges in Implementing Pharma ERP software

The implementation of a Pharma ERP system can face a series of challenges, given the system's complexity and the critical role it plays in business operations. Failing to address these challenges can lead to project failure and substantial financial losses. Here are some common implementation challenges in the pharma industry:

Cost Overruns

Cost overruns in Pharma ERP implementations are the proverbial thorn in the side for many companies. They sneak up, often cloaked as unforeseen expenses in customization, extended timelines, or unplanned technical glitches. Staying within budget bounds requires a watertight strategy, accounting for both predictable and surprise costs along the way.

Implementation Delays

Implementation delays in deploying Pharma ERP systems can cause significant disruption, stretching deadlines and testing patience. These delays may stem from a slew of factors such as scope creep, inadequate resources, or technical challenges. It's critical to anticipate potential bottlenecks and have contingency plans in place.

Employing incremental implementation strategies, ensuring team readiness, and choosing a reliable ERP vendor with a proven track record can contrive to keep your project on the straight and narrow, delivering on time and on target.

Resistance to Change

Resistance to change is the silent adversary of Pharma ERP implementation, often rooted in the comfort of familiar workflows and the trepidation ahead of new system landscapes. It manifests in slowed adoption rates, lowered morale, and even outright pushback.

To dismantle these barriers, foster a culture receptive to change through transparent communication and by illustrating the direct benefits to all users. Engaging and empowering your team from the get-go with inclusive training programs and involvement in system design can transform skeptics into champions of change.

Inadequate Training

Inadequate training is often a stumbling block in Pharma ERP assimilation, leading to underutilization of the systems and diminished returns on investment. When it comes to user training, a one-size-fits-all approach seldom does the trick.

Tailored, role-specific training that takes into account different learning paces and styles ensures that each member of your team can harness the full potential of the ERP. Investing in comprehensive training programs—encompassing interactive sessions, hands-on workshops, and continuous learning opportunities—builds proficiency and advocacy within your workforce.

Lack of Executive Support

Lack of executive support can be the Achilles' heel of a Pharma ERP project, leaving transformative efforts adrift. Executive sponsorship is not just ceremonial; it's foundational, setting the tone for organizational commitment and aligning the ERP initiative with business strategy.

When leaders rally behind the system’s adoption, it casculates credibility and urgency throughout the company, motivating teams and surmounting inertia. It's about driving the vision home and ensuring that the budget, resources, and organizational willpower are in full force to make the ERP a cornerstone of the business's future.

Data Migration Issues

Data migration is critical during the shift to a new Pharma ERP system, yet it's often fraught with complexities and challenges. Ensuring data integrity while transitioning from legacy systems to modern platforms requires a deft hand; any misstep can lead to data loss, errors, and operational hiccups.

Effective data migration demands a strategic approach, meticulous planning, and robust validation processes to secure a foundation of reliable data. Engage with experts who can navigate the delicate process, ensuring the historical data is not just moved, but also transformed and optimized for the new ERP landscape.

How to Resolve the Common Pharma ERP Implementation Challenges

While the aforementioned challenges can complicate the ERP implementation process, several proven strategies can help mitigate these issues. Implementing these strategies can ease the transition to the new system and ensure that it delivers the anticipated benefits.

Comprehensive Planning

Comprehensive planning is the blueprint for success in Pharma ERP implementation, where strategic foresight meets meticulous organization. It's not simply about timelines and to-do lists; it's about envisioning the entire lifecycle of your ERP journey and developing a master plan.

This includes identifying business objectives, resource allocation, risk management, and post-implementation evolution. With comprehensive planning, you're not just guessing the future; you're designing it, step by calculable step, ensuring that the pursuit of your Pharma ERP system aligns seamlessly with your company's broader vision and operational needs.

Invest in Training and Change Management

Investing in training and change management is like equipping your workforce with the armor and acumen for the upcoming revolution a new Pharma ERP system heralds. It's about more than just teaching them how to use new software; it's about helping them understand why change is happening and how they can be a driving force for it. Integrate comprehensive training programs that offer a mix of in-person workshops, on-demand tutorials, and continual support.

To manage change effectively, foster open communication and provide platforms for feedback. These investments create a resilient team that adapoints challenges and embraces innovations, making the ERP implementation a shared mission rather than a top-down directive.

Secure Executive Support

Executive buy-in is contribute to the success of any major project. Actively involve top management in the implementation process and ensure they understand the benefits, costs, and time required for successful ERP implementation.

Data Cleaning

Prior to migrating data to the new ERP system, conduct a comprehensive data cleaning process to eliminate outdated, duplicate, or irrelevant data. This step ensures that the ERP system operates optimally.

Engage a Reliable ERP Vendor

Work with a reputable ERP vendor who understands your business requirements and offers a robust product and strong post-implementation support. They can provide valuable advice and assistance throughout the process.

Adopt a Phased Approach

Instead of implementing the entire ERP system at once, consider a phased approach where you start with critical modules and gradually introduce additional ones. This method can help your team adjust gradually and reduce the risk of system overload.

How to Select Suitable Pharma ERP Software

Choosing an ERP system for a pharmaceutical company involves careful assessment and evaluation as it will shape your business operations. Here's a step-by-step guide to assist in the selection process:

Step 1. Build an ERP Business Case

Identify why your company needs a Pharma ERP system and clearly define your expectations. Understand what functions it needs to cater to, what issues it can solve, and how it can transform your business operations. Documenting a formal business case can help persuade your organization to consider this investment.

Step 2. Compare ERP Vendors

Research existing ERP vendors and analyze their offerings. Pay attention to their industry knowledge, client base, product features, customization capabilities, customer reviews, and after-sale support. The ideal vendor should be supportive of your company's needs and objectives.

Step 3. Get Pricing Estimates

Once you've shortlisted vendors that seem to align with your requirements, get pricing estimates from them. While affordability matters, it shouldn’t be the only criterion. The software's ability to meet your needs and return on investment (ROI) should be the primary concern.

Step 4. Organize a Solution Demo

Many ERP vendors offer demos to help you understand their software functionalities better. Utilize these demos to comprehend how these tools can be integrated into your operations and how they can enhance your business performance.

Step 5. Define ERP Requirements

Define your requirements for the ERP system based on your business needs, difficulty points that need resolution, and the functionalities you expect from it. This document can serve as a reference point in identifying the right ERP system.

Step 6. Shortlist Potential Vendors

After thorough research, demos, and price estimates, shortlist 4-8 vendors based on their potential to meet your requirements, their reputation, system adaptability, user-friendliness, client feedback, and other relevant factors.

Step 7. Make the Final Choice

Based on all the aforementioned evaluation factors, select the most apt software and vendor for your pharmaceutical company's needs. The right ERP system has the potential to streamline processes, enhance productivity, ensure compliance, and contribute to your company’s growth and success.

Create an efficient Pharma ERP Software with Kohezion

Highly customizable and user-friendly, Kohezion provides a powerful and adaptable solution that does not demand extensive coding knowledge. It effectively addresses the pain points of pharmaceutical business owners, as it integrates various departments to provide real-time information. From project management to CRM and inventory tracking, Kohezion serves as a comprehensive ERP solution ensuring traceability, optimizing time, and enhancing overall performance.

Conclusion

These top-rated Pharma ERP software solutions for 2024 offer a comprehensive range of features tailored to meet the unique demands of the pharmaceutical industry, ensuring regulatory compliance, enhancing operational efficiency, and improving overall productivity.

These advanced systems integrate various functions such as inventory management, quality control, and supply chain optimization, providing a holistic approach to managing complex pharmaceutical operations. With these cutting-edge ERP solutions, pharmaceutical companies can streamline their processes, reduce costs, and maintain a competitive edge in an increasingly challenging market.

Start building with a free account

Frequently Asked Questions

To determine which pharma ERP software is right for your company, consider your specific needs such as regulatory compliance, scalability, and integration with existing systems. Evaluate options based on their ability to streamline processes, enhance data accuracy, and support quality control. Assess the software’s user-friendliness, vendor reputation, customer support, and cost-effectiveness to ensure it aligns with your operational goals and budget.

Yes, many pharma ERP systems are designed to adapt to changing pharmaceutical regulations. These systems typically include features for real-time updates and compliance management, ensuring that companies can quickly and efficiently adjust their processes to meet new regulatory requirements. Reputable ERP vendors like Kohezion often provide regular updates and support to help users stay compliant with evolving standards in the pharmaceutical industry.

The cost of ERP for pharmaceuticals varies widely depending on factors such as the size of the company, the complexity of its operations, the specific features required, and the vendor chosen. On-premise ERP systems typically involve higher upfront costs, including software licenses, hardware, and implementation fees, while cloud-based solutions may offer more flexible, subscription-based pricing. The costs can range from a few thousand dollars per year for small companies to several hundred thousand dollars or more for larger enterprises with extensive customization and integration needs.